Table of Contents

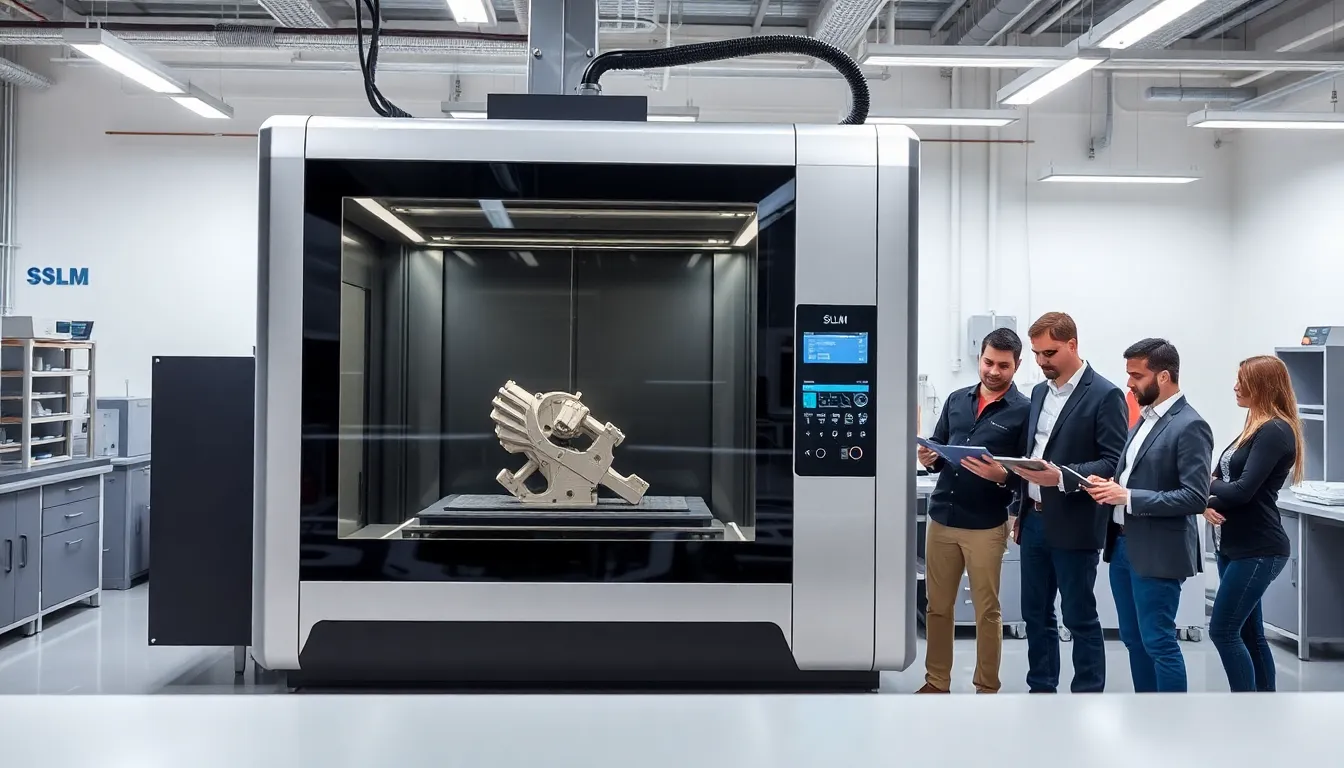

ToggleEver thought of creating complex metal parts as easy as pie? Enter SLM 3D printing, a technology that promises to revolutionize manufacturing faster than you can say ‘layer by layer.’ If you’ve ever dreamed of producing lightweight, intricately designed items on demand, this is the magic wand you’ve been waiting for. Let’s jump into the intriguing realm of SLM 3D printing and discover how it’s reshaping industries one metal powder at a time.

What Is SLM 3D Printing?

At its core, SLM, or Selective Laser Melting, refers to a groundbreaking additive manufacturing process. It utilizes powerful lasers to melt and fuse fine metal powders, building up components layer by layer. Unlike traditional manufacturing methods that often involve subtracting material, SLM focuses on creating components precisely from the ground up, which means less waste and more creativity in design.

Visualize it as crafting a beautiful sculpture, but instead of chipping away at a block of marble, you’re strategically placing molten metal to form an object in 3D. So, whether you’re a tinkerer at heart or part of a corporate production team, SLM 3D printing offers a tantalizing glimpse into the future of manufacturing.

The SLM Process Explained

Understanding the SLM process involves breaking down its major steps:

- Designing a 3D Model: Everything starts with a digital model. Engineers use CAD (computer-aided design) software to create a highly detailed blueprint.

- Preparing the Printer: Next, the SLM printer is prepped. Fine metal powder, often made from alloys or pure metals, is loaded into the build chamber.

- Layering: The laser moves precisely over the powder bed, melting it according to the design layer by layer. As each layer is completed, the build platform lowers, and a fresh layer of powder is distributed.

- Cooling and Finishing: Once the printing is done, the part goes through cooling, followed by post-processing procedures like sintering or surface finishing to enhance its mechanical properties and appearance.

This multi-step process minimizes the risk of errors and drastically reduces production time, making SLM a game-changer for various industries.

Materials Used in SLM 3D Printing

Choosing the right material is pivotal in SLM 3D printing. A variety of metals can be used, including:

- Stainless Steel: Renowned for its strength and resistance to corrosion.

- Aluminum: Lightweight yet strong, making it ideal for aerospace and automotive applications.

- Titanium: Favored in medical implants due to its biocompatibility.

- Cobalt Chrome: Highly durable, which is a favorite in dental and orthopedic applications.

The versatility of materials significantly expands the horizon of what can be created. Different materials yield different characteristics, allowing manufacturers to pick and choose based on the specific requirements of their projects.

Applications of SLM 3D Printing

SLM 3D printing finds its place across an array of industries, some notable applications include:

- Aerospace: Lightweight, complex parts that enhance fuel efficiency while maintaining strength.

- Automotive: Custom parts can be produced on-demand, reducing inventory costs and waste.

- Medical: Surgical instruments and prosthetics designed specifically for individual patients.

- Tooling: Durable, intricate tooling for manufacturing processes which was once considered impossible to fabricate.

Each of these applications showcases SLM’s ability to streamline and innovate traditional manufacturing practices, highlighting technology’s significant impact.

Advantages of SLM 3D Printing

The adoption of SLM 3D printing brings a plethora of advantages:

- Customization: Unique designs easily crafted to meet specific needs without the constraints of traditional manufacturing.

- Reduced Waste: Since material is added layer by layer, waste is minimized compared to subtractive processes.

- Speed: Production timelines drastically shorten, allowing for rapid iteration and faster time to market.

- Complex Geometries: Complicated shapes can be manufactured that would be impossible to achieve through traditional methods.

These benefits not only reduce manufacturing costs but also spark innovation across industries, encouraging companies to think outside the box.

Challenges and Limitations of SLM 3D Printing

Even though its many advantages, SLM 3D printing is not without its challenges:

- Cost: High initial investment for machinery and materials can be a barrier for smaller companies.

- Post-Processing: Parts often require additional finishing processes, which can extend overall production time.

- Quality Control: Maintaining consistency across builds can be tricky, requiring meticulous management of parameters during the printing process.

- Material Limitations: Availability and cost of suitable metal powders can pose significant hurdles.

While the technology continues to evolve, manufacturers must navigate these bumps in the road to fully embrace its capabilities.

The Future of SLM 3D Printing

Looking ahead, the future of SLM 3D printing is bright with the promise of exciting developments:

- New Materials: Ongoing research into diverse materials that can broaden application ranges.

- Improved Technology: Advances in laser technology could lead to faster print speeds and better build quality.

- Sustainability: As industries aim for greener practices, SLM could play a vital role in sustainable manufacturing through reduced waste and energy efficiency.

With these promising trends, SLM 3D printing is set to redefine manufacturing as we know it. The embrace of this technology reflects a forward-thinking mindset that prioritizes innovation.