Table of Contents

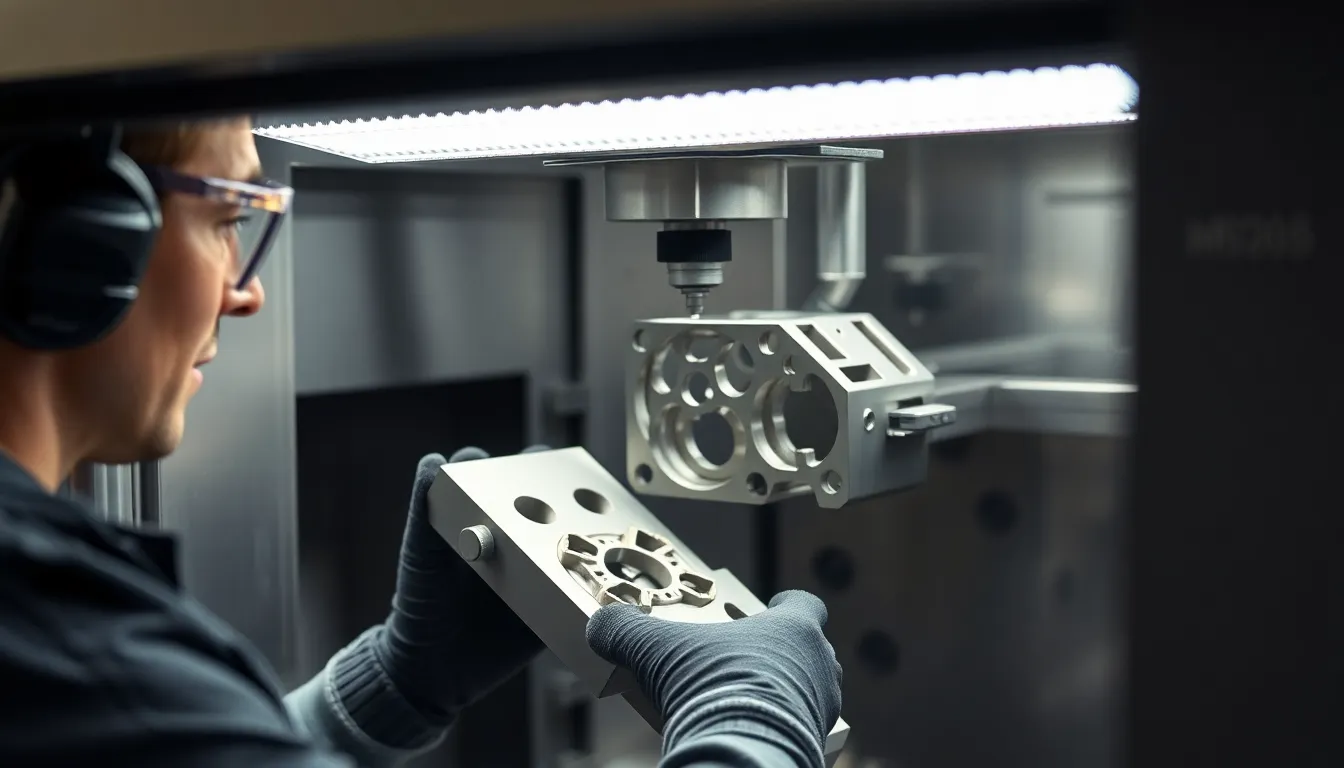

ToggleIn the rapidly evolving landscape of manufacturing, metal additive manufacturing stands out as a game-changer. This innovative technology uses 3D printing techniques to create complex metal components layer by layer, pushing the boundaries of design and efficiency. As industries seek to streamline production and reduce waste, metal additive manufacturing offers a compelling solution that combines precision with flexibility.

From aerospace to automotive, the applications of this technology are vast and varied. It not only enables the production of lightweight structures but also allows for intricate designs that traditional methods can’t achieve. As businesses embrace this cutting-edge approach, understanding its benefits and challenges becomes crucial for staying competitive in today’s market.

Overview of Metal Additive Manufacturing

Metal additive manufacturing uses advanced 3D printing technologies to produce metal parts layer by layer. This approach allows for the creation of complex geometries that conventional manufacturing methods can’t achieve. Industries such as aerospace, automotive, and medical leverage these capabilities for prototypes and end-use components.

Key technologies in metal additive manufacturing include:

- Selective Laser Melting (SLM): SLM employs a high-powered laser to fuse metal powder particles together, resulting in dense, high-strength parts.

- Electron Beam Melting (EBM): EBM utilizes an electron beam in a vacuum to melt metal powder, offering high build rates and excellent material properties.

- Binder Jetting: This method involves binding metal powder with a liquid binder to create a green part that undergoes sintering for final density.

- Directed Energy Deposition (DED): DED involves feeding metal wire or powder into an energy source to create parts through additive material deposition.

Metal additive manufacturing provides advantages such as reduced lead times, lower material waste, and enhanced design flexibility. It enables lightweight structures, critical in industries like aerospace, where weight reduction improves fuel efficiency.

Despite its benefits, challenges exist, including high initial costs, the need for specialized equipment, and potential material inconsistencies. Companies integrating this technology must weigh the long-term benefits against these obstacles to optimize production processes.

Key Technologies in Metal Additive Manufacturing

Metal additive manufacturing encompasses several key technologies that facilitate the production of complex metal parts. Two major methods include Powder Bed Fusion and Directed Energy Deposition.

Powder Bed Fusion

Powder Bed Fusion (PBF) involves selectively melting metal powder layers using focused energy sources. This method primarily includes Selective Laser Melting (SLM) and Electron Beam Melting (EBM).

- Selective Laser Melting (SLM): SLM uses a high-powered laser to melt and fuse metal powder particles layer by layer. It allows for the creation of intricate geometries with high density and excellent mechanical properties, making it suitable for high-performance applications in aerospace and medical industries.

- Electron Beam Melting (EBM): EBM employs an electron beam in a vacuum to melt the metal powder. This process provides high build rates and is particularly effective for titanium and other high-temperature alloys. EBM enables large-scale part production while ensuring minimal residual stresses.

Directed Energy Deposition

Directed Energy Deposition (DED) uses focused energy to melt materials as they are deposited, allowing for both additive manufacturing and repair of existing components.

- Process Overview: DED combines the principles of welding and additive manufacturing. It utilizes a heat source, such as a laser or electron beam, to melt the material while feeding metal powder or wire into the melt pool.

- Advantages: DED offers versatility in materials, including alloys, ceramics, and composites. This technology effectively builds up parts, repairs damaged components, and even adds new features to existing structures, facilitating flexibility in manufacturing processes.

Understanding these key technologies enables companies to choose the most appropriate method for their specific manufacturing needs and take full advantage of what metal additive manufacturing offers.

Advantages of Metal Additive Manufacturing

Metal additive manufacturing offers several advantages, including design flexibility and material efficiency, which are crucial for modern production environments.

Design Flexibility

Metal additive manufacturing enables the creation of intricate geometries that traditional manufacturing methods cannot achieve. Designers can produce complex structures, optimize weight, and integrate functional features directly into parts. This capability allows for the design of lightweight components that maintain strength and durability. Additionally, iterative design processes become more efficient, as modifications can be implemented rapidly without the need for expensive tooling changes.

Material Efficiency

Material efficiency is a significant benefit of metal additive manufacturing, as it significantly reduces waste compared to conventional methods. Traditional machining often involves subtractive processes, where up to 80% of material can be wasted. In contrast, metal additive manufacturing builds components layer by layer, utilizing only the necessary material, which leads to improved resource utilization. This approach not only conserves materials but also reduces costs associated with excess scrap and tooling. Furthermore, the ability to use high-performance metal powders allows for the production of parts with enhanced mechanical properties and increased performance in demanding applications.

Applications of Metal Additive Manufacturing

Metal additive manufacturing finds extensive applications across various industries, significantly enhancing production processes and product performance. Its adaptability and efficiency offer substantial benefits in sectors like aerospace and medical.

Aerospace Industry

Metal additive manufacturing plays a vital role in the aerospace industry, where it enables the production of lightweight, high-strength components that meet rigorous industry standards. Techniques such as Selective Laser Melting (SLM) support the creation of complex geometries, allowing for designs that optimize weight and aerodynamics. Through these processes, manufacturers produce parts like fuel nozzles and structural components that improve fuel efficiency while reducing overall weight. The technology’s capability to rapidly prototype parts also facilitates quicker design iterations, meeting the industry’s demand for innovation and rapid deployment.

Medical Industry

In the medical industry, metal additive manufacturing significantly enhances the production of customized implants and surgical instruments. The technology allows for the fabrication of complex structures tailored to individual patient needs, such as personalized knee and hip implants that offer improved fit and functionality. Techniques like Electron Beam Melting (EBM) enable the production of titanium components known for their biocompatibility and strength. This application not only improves patient outcomes but also allows for streamlined manufacturing processes that reduce lead times and costs associated with traditional manufacturing methods.

Challenges and Limitations

Metal additive manufacturing faces several challenges and limitations that may affect its broader adoption across industries. Understanding these factors is essential for companies looking to leverage this technology effectively.

Material Properties

Material properties of parts produced via metal additive manufacturing can vary significantly based on the selected process and parameters. Variations in microstructure, such as porosity and residual stress, can impact strength and durability. Parts may exhibit anisotropic behaviors, meaning their mechanical properties differ based on the build orientation. This inconsistency necessitates thorough testing and validation to ensure parts meet required performance standards, particularly in critical applications like aerospace and medical devices.

Equipment Costs

Equipment costs associated with metal additive manufacturing can be substantial. Initial investments for machines such as Selective Laser Melting and Electron Beam Melting units can exceed $1 million. Additionally, maintaining and operating these systems requires specialized training and skilled personnel, further contributing to operational expenses. Companies should assess the long-term return on investment when integrating this technology into existing production processes, ensuring that the benefits justify the capital outlay.

Future Trends in Metal Additive Manufacturing

Technological advancements shape the landscape of metal additive manufacturing, creating new opportunities and applications across various industries. One significant trend is the integration of artificial intelligence (AI) and machine learning (ML) into the manufacturing process. These technologies enhance process optimization, monitor material properties in real-time, and predict potential failures, improving quality and consistency in production.

Increased material options also stand out as a future trend. Researchers are developing new metal alloys and composite materials that open avenues for producing stronger, lighter, and more durable components. This expansion in material diversity supports various applications, such as aerospace and medical devices, requiring specific mechanical properties and biocompatibility.

Moreover, hybrid manufacturing systems are gaining traction in the industry. These systems combine traditional manufacturing techniques with additive processes, enabling efficient repair and modification of components. For example, integrating machining and metal additive manufacturing allows for precise finishing that enhances surface quality and dimensional accuracy.

Sustainability continues to play a crucial role in shaping metal additive manufacturing’s future. The push for reducing carbon footprints is leading companies to adopt greener practices. Using recycled materials and minimizing waste through additive processes aligns with industry sustainability goals, promoting a more eco-friendly manufacturing approach.

Finally, advancements in post-processing techniques contribute significantly to the field. Improved methods for finishing, such as machining, heat treatment, and surface treatment, enhance the mechanical properties of 3D-printed parts. These developments ensure that the final products meet stringent industry requirements, facilitating broader acceptance of metal additive manufacturing across various sectors.

Metal additive manufacturing is reshaping the landscape of production across various industries. Its ability to create complex geometries and lightweight components offers unparalleled design flexibility and material efficiency. As companies navigate the challenges of high initial costs and the need for specialized skills, the benefits of reduced waste and enhanced performance cannot be overlooked.

With the ongoing advancements in technology and materials, the future of metal additive manufacturing looks promising. The integration of AI and the development of new alloys are set to further enhance its capabilities. Embracing this innovative approach will be crucial for companies aiming to stay competitive in an ever-evolving market.